VCI Cardboard (Corrugated Board with Volatile Corrosion Inhibitor)

Model Selection for the VCI Cardboard

SF/H108-760WP

Specifications

Specific Weight: 760g/m2

Thickness: 3~4mm

Corrosion Prevention Methods for Ferrous Metals

The VCI cardboard is a kind of corrugated board coated with volatile corrosion inhibitors, and thus it is a commonly used corrosion prevention method for packaging of ferrous metals.

How is the VCI Cardboard Created?

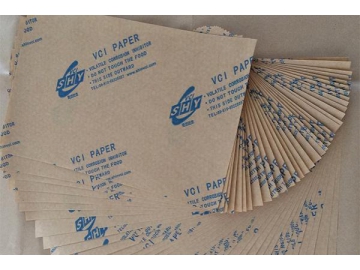

VCI cardboard is made form PH neutral cardboard with VCI spread over on one or both sides which has been through a corrugating machine or flute laminator to gain wavy ridges called flutes. The continuous run of paper is then cut on a die-cutter into individual VCI corrugated sheets. VCI cardboard provides cushioning, buffering, and rust prevention to whatever is packed inside it. VCI paper products are typically converted into interleaving, corrugated box, etc.

Applications of VCI Cardboard

Interleaving

VCI corrugated sheets can be designed as sheeting and interleaving between layers of metal parts. To unitize the many components, water-proof VCI film is needed to bring layers together by tightly wrapping around them. The outer cover for the whole pack should be a rigid cardboard box. Please ensure the package is tightly sealed.

Box Partitions

Use method of box partitions is pretty much the same as what is described above.

Packaging

Convert VCI cardboard into a cardboard box. Put metal components to be packed inside the box and use adhesive tapes or stretch films to seal the package.

Storage

Please keep VCI cardboard packaging material dry, out of direct sunlight, and away from acidic, alkaline or salty conditions. The shelf life of VCI cardboard sheets is 12 months.