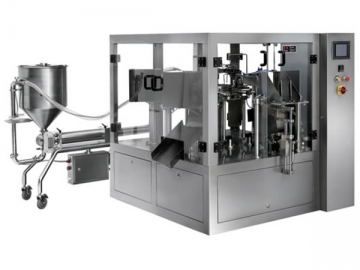

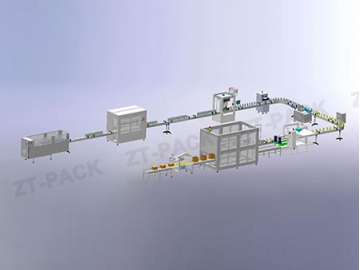

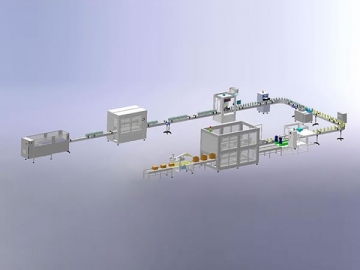

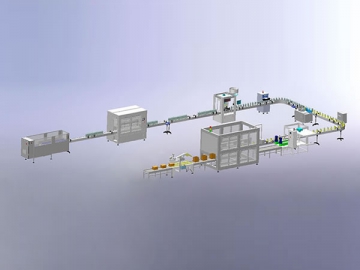

Liquid and Thick Liquid Fill Seal Production Line

Applications

The fill-seal production line can be used to deal with all kinds of liquid and think-liquid (sauce), fruit juice, seasoning sauce, tomato sauce, peanut butter, jam, chili sauce, hand sanitizer, liquid detergent, and more.

Main Features

1. A wide range of pouches: all kinds of pre-made pouches such as flat and stand-up pouches (with/ without zip).

2. Wash-down: RezPack liquid and thick liquid fill seal production line provides direct water-washing of its machine surface, so as to timely clean up the corrosive materials. This helps enhance the hygiene level, safety, and prolong the service life.

3. Easy to operate: PLC controller and color touch-screen, fault indication on the touch screen.

4. Easy to adjust: only about 10 minutes to change different pouches.

5. Frequency control: speed of the liquid and thick liquid fill seal production line can be adjusted by frequency conversion within the range.

6. High automation: The liquid and thick liquid fill seal production line is unmanned in weighing and packing process, machine alarm automatically when failure.

7. Waterproof design: As the machine surface can be washed down, the bag packing machinery provides easy cleaning and long service life.

| Production Line | Liquid and Thick Liquid Fill-Seal Production Line |

| Bag types | Standup bag, portable bag, zipper bag, 4-side sealing bag, 3-side sealing bag, paper bag, etc., and all kinds of compound bags |

| Bag sizes | W: 80-320mm; L:100-430mm |

| Filling range | 5-1500g |

| Packing speed | 25-45bags/min (depending on the product and filling weight) |

| Auxiliary equipment | Liquid filling machine |

| Package accuracy | Error ≥±1% |

| Total power | 2.3kw |

| Compressed air | ≥0.4 m3/min |