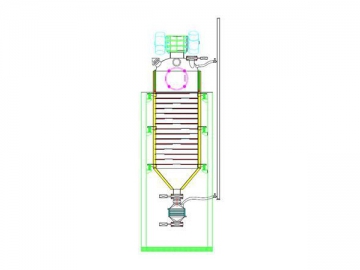

Spray Dryer (for Sticky Material)

The ZPG model spray dryer for sticky material is specially designed for raw material which clings to the inside chamber and has a low melting point. The liquid dryer can process liquid raw materials such as vegetable extract, juices or other liquids with a high sugar content. The design of the ZPG spray drying machine depends on the specific application.

Features of the ZPG Spray Dryer

1. The vegetable processing equipment’s tower has a cooling air jacket, which reduces the chamber’s temperature to prevent the product from melting.

2. Pneumatic chamber vibrator helps the spray dryer to dispense sticky, solid products.

3. Holes on both the tower and pipe of this juice processing equipment allow for easy cleaning and maintenance.

4. The ZPG spray dryer has an optional heating agitator tank for raw liquid material.

5. A small discharge angle and arc design make for a smooth exit flow.

6. Cooling air sweep (inside the chamber) is optional.

| Model | ||||||||

| Evaporated moisture (kg/h) | 5 | 25 | 50 | 80 | 100 | 150 | 200 | 300 |

| Input capacity (kg/h) | 5-8 | 25-34 | 50-68 | 80-108 | 100-135 | 150-203 | 200-270 | 300-406 |

| Output capacity (kg/h) | 0.25-2 | 4.8-7.2 | 9.2-14 | 14.8-22.4 | 18.4-28 | 28-42 | 36.8-56.4 | 55-85 |

| Solid content of liquid raw material (%) | 18-25 | |||||||

| Moisture content of product (%) | 3-5 | |||||||

| Power (kw) | 36 | 63 | 99 | 132 | 153 | 204 | 246 | 330 |

| Heating resource | Steam E lectric | |||||||

| Collection method and rate | Second grade s cyclone separator 98% or one grade cyclone separator plus washing tower ≥ 99.5 % | |||||||

| Inlet air temperature (℃) | 150-200 | |||||||

| Outlet air temperature (℃) | 80-100 |