10-30L Automatic Drum Filler (with Weight Scale), ZCJ-6

The automatic drum filler with weight scale is used to fill containers weighing between 10-30L for products in the food, pharmaceutical, cosmetic, and chemical industries. The liquid filling machine feeds bottles in, fills them based on weight, and feeds them out again. Each filling head can be adjusted via an easy to use PLC touch screen. The weight drum filling machine meets GMP standards and is safe to use with food.

- Number of filling heads: 6

- Filling range: 5-30kg

- Bottle size range:

L: 160mm~360mm

W: 140mm~260mm

H: 250mm~500mm

(Min: 140 x 200 x 320 mm, Max: 260 x 290 x 500 mm) - Diameter of bottle opening: ≥Φ40mm

- Power Supply: ~ 220 V, 50 Hz

- Total power: 2.5 kW

- Weight: about 800 kg

- Air consumption: 120L/min

- Measurement accuracy: ± 0.5% (Note: Filling accuracy depends on the viscosity of the material)

- Production capacity: ≤480 bottles/hour

- Outline Dimensions (L x W x H): 3500mm x 1700mm x 2300mm

- Bottle feeding direction: From left to right

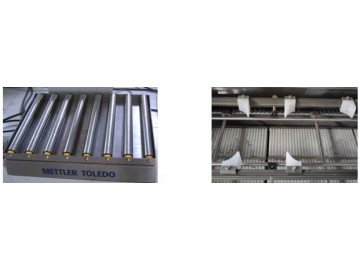

1. Uses a weight sensor and control meter from the US brand METTLER TOLEDO for precise filling and smooth conveying.

2. Fast and slow speed valves ensure filling accuracy and helps eliminate splashing and foam.

3. Under the filling nozzle is the movable dip collecting cup which collects any residue so it won't enter the bottle.

4.Weighing control cabinet uses a standard RS-483 interface. Gross weight or net weight filling can be pre-set. Actual filling amount shows in real time.

5. Sensors detect when the drum is empty and won't fill or when the bottle is not in the right position.

6. Individual electric cabinet's parts such as PLC, HMI, frequency converter and power switch are made of imported parts from Schneider in France for stability and longevity.

7. Made of SUS304 stainless steel. Teflon filling scale and the sealing.

8. Real-time counting and precision of filling within ± 1%. Alarms sound if there are any problems.

9. Easy to adjust filling specifications between projects.

10. Customized configurations available.

| Model | ZCJ-4 | ZCJ-6 |

| Dimensions | 3000 x 1700 x 2300mm | 3500 x 1700 x 2300mm |

| Filling head | 6 | 8 |

| Capacity ( 5L) | 400B/H | 600 B/H |

| Capacity ( 20L) | 250B/H | 400 B/H |

| Power | 2KW | 2.5KW |

| Type of bottle | length:160 -360mm width:100 -300mm height:250 -500mm | |

| Barrel neck diameter | ≥Φ 40mm | |

| Filling error | ≦ ±0.5%F.S | |

| Filling range | 1000ml--5000ml | |

| Air pressure | 0.6Mpa--0.8Mpa | |

| Power supply | 220V ; 50HZ | |

| No. | Name | Place of origin | Brand |

| 1 | PLC | Japan | Mitsubishi |

| 2 | Inverter | France | Schneider |

| 3 | Load cell | USA | METTLER TOLEDO |

| 4 | Angle seat valve | Taiwan | Airtac |

| 5 | Solenoid valve | Taiwan | shako |

| 6 | Photo sensor | Japan | Optex |

| 7 | Touch screen | Japan | WEINVEIW |

| 8 | Level button | Mexico | JOHNSON CONTROLS |

| 9 | Diving cylinder | Taiwan | AIRTAC |

| 10 | Power button | France | Schneider |

| 11 | Button | France | Schneider |

| 12 | Magnetic switch | Taiwan | AIRTAC |

| 13 | Oil-water separator | Taiwan | SHAKO |

| 14 | Relay | Japan | Omron |