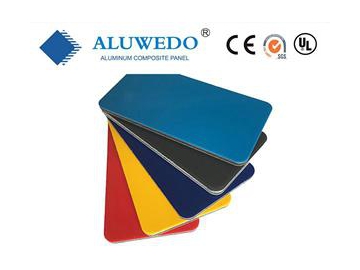

Distinguished Properties

1. Aluwedo mass finish aluminum composite panel reaches a 25% less of finish comparing with others

2. This kind of Aluminum composite panel is applicable in screen printing and direct-to-substrate digital printing

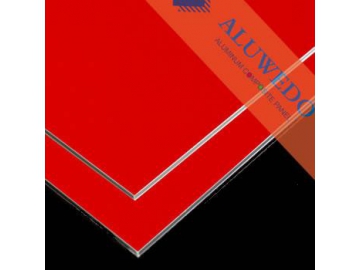

3. The ACP is of smooth and flat surface; printed film will help to extend the panels' service life

4. The panel surface can be coated to be brightened and attractive

5. Featuring outstanding weather resistance

6. The ACP comes with at least 5 years guarantee in outdoor applications

7. UV protection

8. It can be routed and returned to add dimension or roll-formed to deliver sweeping curves

9.PE colours come with a 5 year external guarantee.

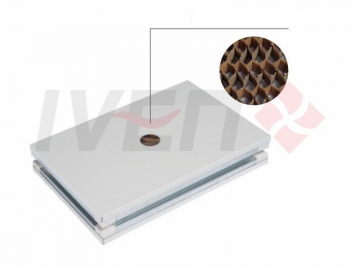

10. Exceptionally rigid against comparable traditional sign materials; shown is a comparison table of 4 kinds of panels:

| Material | ACP | Aluminum panel | PVC panel | Acrylic panel |

| Thickness | 3mm | 2.4mm | 11.1mm | 6.8mm |

| Size | 1m2 | 1m2 | 1m2 | 1m2 |

| Weight | 3.8kg | 6.5kg | 5.6kg | 8.2kg |

Raw Material

a. High strength aluminum alloy A1100

b. LDPE core

c. Surface: PE coating & adhesive film from Dupont

Aluminum Composite Material Specification and Dimension

1. Standard Specification

a. Thickness: 2mm (0.08"), 3mm (0.12"), 4mm (0.16"), 5mm (0.2"), 6mm (0.24");

Recommended thickness: 4mm (0.16");

b. Width: 850mm – 2000mm (34" – 80");

Recommended width: 1220mm (48.8"), 1250mm (50"), 1500mm (60"), 2000mm (80");

c. Length: as required;

d. Aluminum thickness: 0.3mm – 0.5mm (0.012" – 0.02");

e. *Custom width and length is available upon request (subject to the minimum order quantities)

f. Tolerance (mm)

thickness: ±0.2

width: ±0.2

length: ±3

diagonal: ±3

2. Recommended Dimension:

1220mm (4ft)* 2440mm (8ft)* 3mm (0.12")* 0.21mm (0.08")

1500mm (5ft)* 3050mm (10ft)* 3mm (0.12")* 0.21mm (0.08")

Technical Parameters | Panel thickness (mm) | 2 | 3 | 4 | 6 | 8 |

| Aluminium skin thickness (mm) | 0.21 0.30 | 0.40 |

| Weight (Kg/m2) | 3 | 4 | 5 | 6.6 | 9 |

| Standard sizes (mm) | | | | | |

| 1000 x 2440 | * | * | | | |

| 1000 x 3050 | * | * | | | |

| 1220 x 2440 | * | * | * | * | * |

| 1220 x 3050 | | * | | | |

| 1500 x 3050 | * | * | * | | |

| 1500 x 4050 | | * | * | | |

| 2000 x 3050 | | * | * | | |

| 2000 x 4050 | | * | | | |

Dimensional Tolerances | Thickness (mm) | - 0 + 0.2 |

| Width (mm) | ± 2 |

| Length (mm) | ± 3 |

| Diagonal (mm) | ± 5 |

| Thermal expansion | 2.4mm/m at 100˚C temp difference |

| Aluminium thickness (mm) | where applicable as specified in EN485-4

|

Surface Properties | Paint thickness (micron) | 20 |

| Pencil hardness | >hb |

| Toughness of coating | 3t |

| Temperature resistance | -50˚C to +90˚C |

| Impact strength (kg/cm2) | 50 |

| Boiling water resistance | boiling for 2 hours without change |

| Acid resistance | immersed in 2% HC1 for 24 hours without change |

| Alkali resistance | immersed in 2% NaOH for 24 hours without change |

| Oil resistance | immersed in 20# engine oil for 24 hours without change |

| Solvent resistance | cleaned with dimethylbenzene for 100 times without change |

| Cleaning resistance | >1000 times without change |

| Peel strength 180˚ | >5 newton/mm

|

| Panel thickness (mm) | 2 | 3 | 4 | 6 | 8 |

| Sound absorption NRC | 0.05 |

| Sound reduction Rw db | 23 | 24 | 25 | 26 | 27 |

| Water absorption by volume (%) | 0.01 |

| Thermal performance R-values | 0.0047 | 0.0080 | 0.0113 | 0.0180 | 0.0246 |

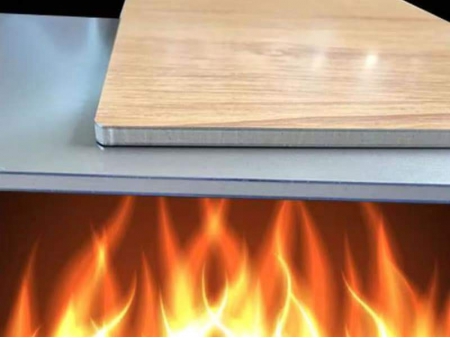

| Core composition | LDPE |

| Fire performance | Class 1 BS476 PT7 |

| Class O BS476 PT6 |

| Tensile strength | 149MPa

|

| Testing item | Standard | Result |

| Unit weight | ASTM D792 | T 3mm=4kg/m2 |

| Thermal expansion | ASTM D696 | 24-28 |

| Thermal deformation temperature | ASTM D648 | 115℃ |

| Thermal conduction | ASTM D976 | 0.102kcal/m.hr℃ |

| Flexural rigidity | ASTM D393 | 14.0*10^5 |

| Impact resistance | ASTM D732 | 1.64kgf |

| Adhesive strength | ASTM D903 | 0.77kg/mm |

| Flexural elasticity | ASTM D790 | 4030kg/mm2 |

| Shear resistance | ASTM D732 | 2.7kgf/mm2 |

| Fire propagation | ASTM E84 | qualified |

| Wind-pressure resistance | ASTM E330 | passed |

| Waterproof property | ASTM E331 | passed

|