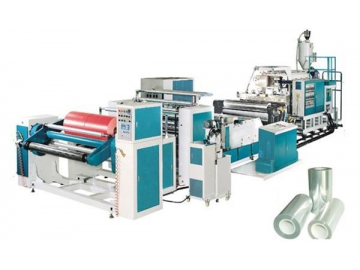

Cast Film Line

One of the remarkable features of the cast film line is its slitting function. Slitting and winding operation for up to five rolls can be set up, which can save the cost of buying slitting machines and can also shorten the production process.

The power consumption of producing every ton of sheet materials is 50%-60% of that of similar products, which shows the system's low energy consumption.

This machine adopts PP colloidal particles as raw materials and can produce CPP sheet materials with thickness of 0.03-0.2mm. The width can be set according to your requirements.

This machine adopts a color human-machine interface and programmable controller, so the operation is safe and convenient and its operation is highly automated, which can satisfy the needs of modern chemical plants to the highest extent.

This cast film line is suitable for use in plastic products factories, soft packaging products factories and stationery products factories.

Finished productsThe main engine of extruding machine can move backwards and forwards, which can increase operational safety.

The crew barrel adopts Italian design and works in with static mixer imported from Europe, which can increase plasticizing capacity, making the film color uniform and improving film quality.

T shape die head adopts American EDI design and is made in Taiwan. It can produce film sheets with uniform thickness.

Italian low carbon alloy steel gearbox is adopted, which makes this equipment show good bearing capacity and wear resistant performance.

SGR system is adopted to control temperature with temperature difference of 1℃, which can precisely control the plasticizing process, film thickness and film flatness.

The embossing roller, with diameter of 600mm, works in with air knife system, double circuit cooling system and microcomputer full-automatic temperature control system to realize the flatness of film sheet and uniformity of thickness.

Automatic winding system

- Slitting device can adjust the width of film sheet.

- Automatic flip cutting device is adopted to increase production efficiency.

- It's equipped with Japanese servo motor and American tension controller. This makes winding speed reach 60m/min, and the winding is smooth.

Electronic control system adopts PLC control and colored human-machine interface, so that the operation is safe and convenient.

Corona treater has different grades for customers to choose and can meet the different budget requirements of customers.

This cast film line can recover all waste materials in time and realize their trimming, slitting and crushing recovery, which can reduce cost.

This machine is improved and designed on the basis of similar machines and has passed CE certification (Certificate number: 28407/475/C).

Technical parameters

| Film Width | Max 1450mm |

| Film Thickness | 0.03mm-0.20mm |

| Effective Winding Width | Max 1450mm |

| Max Rewind Roll Diameter | 700mm |

| Extruding Capacity | 60-230(KG/HP) |

| Power Supply | 140KW |

| Screw Diameter | 100mm |

| L/D Ratio | 1mm:36mm |

| Width of Embossing Roller | 1600mm |

| Machine Dimension L×W×H | 13mm×5.3mm×3.7mm |

| Net Weight | 16T |

| Production Consumption | 80KW |

- Grinder

- Water cooling unit

- Automatic mixer

- Granulator

- Corona treater

- Thermostatic water tank