VCI Film (Heat Shrink Film with Volatile Corrosion Inhibitor)

As a VCI film specialist, CVCI offers an easy, cost-saving way of wrapping your large and bulky equipment by providing an assorted lineup of VCI heat shrink films.

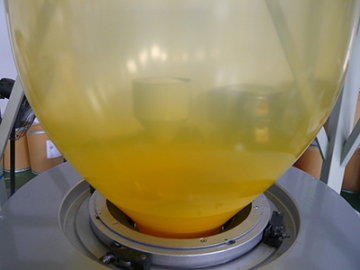

VCI heat shrink film is a perfect combination of volatile corrosion inhibitor and heat shrink technologies. The VCI film is strong and durable for wrapping bulky equipment, and flexible enough to conform around curves and turns of irregular shapes. Packing irregular shapes was once a worldwide problem. VCI heat shrink film is the problem-solver. One benefit of using VCI shrink wrap is that the film eliminates the need of wooden box, which saves money on packaging cost. Popular uses for this VCI film are in wrapping machinery, ships, motors, elevators, construction tools, aircraft engines and components, large pipes, furniture, and any other large-size objects stored outdoors.

Features of the VCI Film

1. Wrap your large equipment, heavy loads, and export shipments with a tough clear plastic film and then shrunk by heating to form a tightly fitting package. Remember that this shrink wrap takes packaging function one step further by adding a molecular VCI layer to the metal surface to offer corrosion protection performance.

2. After being heated, the VCI film has generally a 25%-60% size reduction. In the meantime, the film releases VCI vapor into the enclosed space for corrosion protection.

3. Without the aid of any adhesives or other bonding agents, VCI heat shrink film clings fast to the objects being packaged.

4. Custom printing can be added to the VCI film package, including your trademarks and product introductions, which improves the overall look of your pack.

5. A tight wrap protects packaged equipment from external shock, thus serving as a cushion against stresses.

6. VCI heat shrink film keeps rainwater, moisture, or other contaminants away from the goods being enclosed. VCI film wrapped products can be stored outside and impervious to inclement weather.

7. The shrink wrap generates a pull force of up to 300kg/cm2 during shrinking. This pulling action keeps equipment or metal pieces being packed close together, which makes the film ideal for strapping multiple parts or bulk materials along with pallets. Packing with VCI shrink wrap simplifies the packaging process, saves money on packaging costs, and facilitates transportation over long distance.

8. VCI heat shrink wrap is easy to use, and workable with an automatic packing machine to further save labor costs.

Model No.: SF/SF-150

| No. | Items | Unit | Standards | |

| 1 | Rust Prevention Performance | Volatile Corrosion Inhibition Ability (VIA) | Approved | |

| Contact Corrosion | Tested metal surface shows no signs of pits or erosion. | |||

| 2 | Appearance | No pitting corrosion, discolored patch, bubble, crumple, impurities or other surface defects | ||

| 3 | Width | mm | Width: ±10 | |

| 4 | Thickness | mm | 0.15 ±0.008 | |

| 5 | Thermal Shrinkage Percentage | Longitudinal | % | ≥60 |

| Transverse | ≥20 | |||

| 6 | Tensile Strength | Longitudinal | mpa | ≥12 |

| Transverse | ≥12 | |||

| 6 | Elongation at Break | Longitudinal | % | ≥200 |

| Transverse | % | ≥200 | ||

| 7 | Tear Strength (at right angle) | Longitudinal | Kn /m | ≥40 |

| Transverse | ≥40 | |||

Associated Tools

1. Propane bottle: 1pc, regardless of size

2. Heat gun: 1pc

Method of Use

Wrap VCI film around metal pieces to be packaged. Use a heat gun to spray hot air onto the film. It might take some time for the shrink wrap to respond to the heat. Once it does, the film would shrink to conform to the shape of metal parts being packed. This tightly fitting shrink film keeps water, dust, and friction away. Made of premium quality resins, the VCI film has UV protection for large equipment stored outdoors. The film is tough, flexible, sticky, heat sealable, and wear resistant. Nothing beats it! To reduce packing time and cost, we suggest users convert VCI shrink film into a bag the same size of equipment to be packaged. Care should be taken not to puncture or tear the film. The VCI heat shrink film thickness ranges from 0.15mm to 0.18mm,

Benefits of VCI Heat Shrink Film

1. Shrink-wrapping and Unitizing Palletized Equipment

Equipment, along with the pallet upon which it is stacked, can be shrink-wrapped together into a unit. For that matter, choose a proper length of VCI film, which is generally 10cm to 15cm longer than the equipment to be packed. Tuck the excess length under the pallet. Take the heat gun, get it going from the bottom of pallet and work the way up. Make sure the excess length clings fast to the pallet. For a 2m3 freight, it takes around 2 to 3 minutes to finish packaging with VCI shrink wrap. Once it is done, the whole pack would have no exposed parts. Leave it to cool for about 5-8 minutes.

2. Shrink Wrapping

Roll some VCI film around the equipment to be packed. Where shrink wraps overlap each other, heat them slightly and wait for them to bond. Then blast hot air all over the film and make it shrink tightly onto the equipment. Leave the whole pack to cool for a while. Check the tightly bonded wrap which is like a giant cocoon.