Co-Rotating Twin Screw Pelletizing Line

Plastic Granulator, Plastic Pelletizer, Waste Plastic Recycling Machine, Plastic Pelletizing Line

-

Plastic pelletizing line

-

Plastic pelletizing line

-

Water-ring pelletizing line

SHJ series adopts a random combination structure in assembling elements. It is multi-purpose: by changing the combination of different parts, diversified processing requirements can be met.

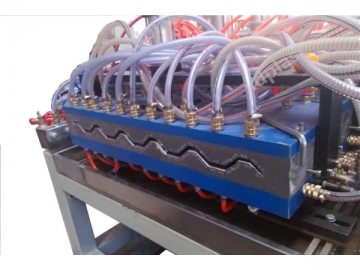

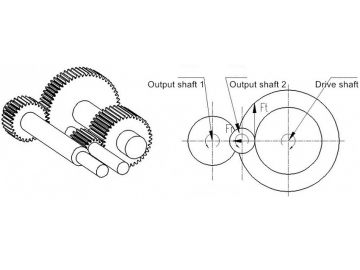

The transmission box of the extruder is of compact structure, featuring high rotation speed, large torque output and stable running. The extruder barrel is made of double-layer wear-resistance alloy steel a301, with a hardness of HRC60-64. Screw of the plastic extruder is made from high-speed tool steel W6Mo5Cr4Vo2, the hardness of which reaches HRC58-62 after vacuum quenching treatment. It is distinguished for high abrasion resistance and long service life.

With a digital temperature control for the barrel, the processing temperature is controlled automatically and precisely. Thermocouple and pressure sensor is employed for extruder head.

Advantages of the Machine Structure

The diversified combination of the machine elements allows for much more applications of the extruder. Different processing tasks can be accomplished simply by changing the arrangement of some barrels or screws. This structure allows for high processing accuracy, since the temperature of each barrel section can be set singly. The barrel surface is highly abrasion and corrosion resistant. The combination of unique speed reducer and transmission system, large torque, high-precision gear, reasonable oil-immersed forced lubrication system, accompanied with interlock protection device, provides a powerful guarantee for the machine’s stable running. The involute splined mandrel supports the max bearing capacity and high torque.

Besides, the plastic pelletizing machine employs personalized control system, vibration and noise control system, digital display, PLC system, and PEC system control.

For machine installing, it is only need to place it on flat ground, with no foundation needed.

Raw Materials

Acceptable materials: ABS, EVA, TPE, TR, wires, PVC, TPV, carbon black masterbatch, Calcium carbonate masterbatch, TPR, PET, etc.

The plastic extrusion machine is able to conduct pelletizing for filled plastic, modified plastic, strengthened plastic, fiber reinforced plastic, WPC, elastomer, cable materials, color masterbatch, and recycled plastic, etc. Clients have access to change the parameters.

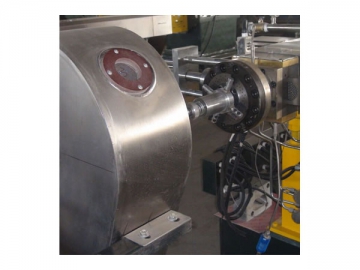

Pelletizing Method

Main pelletizing approaches encompass: underwater strand pelletizing, air-cooled die-face pelletizing, water-cooled die-face pelletizing, water ring die-face pelletizing, eccentric water-spray pelletizing, and underwater pelletizing. The filters can be replaced in various methods. This plastic granulator is of high-precision temperature control, large output and high durability.

-

Air-cooled die face pelletizing

-

Water-ring die face pelletizing

-

Masterbatch particles

-

PE particles

| Model | Diameter (mm) | Aspect ratio L/D | Rotating speed (r/min) | Motor power (kw) | Extrusion volume (kg/h) | |

| 22 | 32-44 | 600 | 5.5 | 0.5-10 | ||

| 31 | 32-48 | 500 | 11 | 5-30 | ||

| 600 | 15 | 5-40 | ||||

| 35.6 | 32-52 | 600-800 | 15-22 | 30-70 | ||

| 35.6 | 32-52 | 600-800 | 15-22 | 30-70 | ||

| 41 | 32-64 | 400 | 22 | 100-120 | ||

| 41 | 32-52 | 600 | 30 | 100-160 | ||

| 41 | 32-52 | 600 | 45-55 | 150-220 | ||

| 50.5 | 32-52 | 500 | 45-55 | 180-270 | ||

| 51.5 | 32-60 | 600 | 90-132 | 682 | ||

| 62.4 | 32-64 | 600 | 90 | 250-350 | ||

| 62.4 | 32-64 | 600 | 110 | 300-400 | ||

| 62.4 | 32-64 | 600-800 | 110-160 | 350-500 | ||

| 71 | 32-64 | 600 | 132 | 350-550 | ||

| 71 | 32-64 | 600 | 160 | 400-600 | ||

| 71 | 32-64 | 600-800 | 200-250 | 600-800 | ||

| 93 | 32-64 | 500 | 250 | 600-1000 | ||

| 93 | 32-64 | 600 | 315 | 800-1200 | ||

| 93 | 32-64 | 600-800 | 400-450 | 1200-1600 | ||

| 1333 | 32-64 | 500 | 550 | 1500-2250 |

| Model | |||||||

| Technique | Typical materials | Pelletizing capacity (kg/h) (reference) | |||||

| Mixing and modification | PE, PP, PS SBS; PA EPDM; PP NBR; EVA silicone rubber | 2-10 | 30-80 | 100-180 | 160-280 | 350-500 | 700-1100 |

| PE, PA, PC, CEP ABS (alloy) ; PBT PET; PP PE | 2-10 | 25-60 | 80-180 | 160-250 | 300-400 | 600-1000 | |

| Filling and modification | PE, PP, EVA CaCO₃, talc, titanium dioxide; ABS, PC, PS Al(OH)3, Mg(OH)2, antimony oxide | 2-10 | 30-60 | 100-200 | 200-400 | 300-550 | 700-1000 |

| PP, PA, ABS iron powder, sulfur powder, ceramic powder | 3-15 | 50-90 | 120-250 | 250-400 | 400-600 | 900-1200 | |

| Functional master batch | PP, PA, ABS, PBT flame retardant, and other additives | 2-10 | 30-60 | 100-180 | 200-300 | 350-450 | 800-1100 |

| PE, PP, PS starch, degradable masterbatch | 2-10 | 30-50 | 90-150 | 150-300 | 200-350 | 600-800 | |

| PE Anti-fog drops, stabilizing agent, anti aging/droplet masterbatch | 2-10 | 30-50 | 70-100 | 170-220 | 250-350 | 600-750 | |

| PE, EVA, ABS carbon black, black masterbatch | 2-8 | 20-40 | 50-100 | 150-220 | 220-320 | 400-700 | |

| Color master batch | PE, PP, ABS, AS, PA, EVA, PET pigments and additives | 2-10 | 30-50 | 80-150 | 150-250 | 250-350 | 500-750 |

| Glass fiber/ carbon fiber reinforcing | PP, PBT, ABS, AS, PA, PC, POM, PPS, PET long fiber, staple fiber, carbon fiber, whisker | 1-8 | 30-80 | 100-180 | 180-300 | 250-450 | 550-900 |

| Cable materials | HDPE, LDPE, LLDPE, MDPE, EVA, PVC, PP and other cable insulation or cable cover materials; PE, silane cable materials, etc. | 2-8 | 20-80 | 80-180 | 150-300 | 250-450 | 500-900 |

| Special materials | EVA hot-melt adhesives, PU, fluororubber, Fluorine plastic, PP material for cigarette filter, TPR for shoes, pet food | 20-100 | 40-200 | 100-300 | 150-500 | 450-1100 | |

| Extrusion materials | Polyamide, polymeric melt polymerization, PU, polycarbonate polycondensation reaction | 15-35 | 80-150 | 180-250 | 250-400 | 450-700 | |

| Devolatilization | CCP, SAP, CSM | 10-40 | 50-100 | 80-200 | 120-300 | 200-500 | |

| Powder | Polyester, Epoxy, Propyl esters, PU, acrylate | 80-120 | 180-280 | 350-480 | 600-780 | 1200-1400 | |