ABM Quick Span / K-Span Roll Forming Machine, CS-914-650

Features

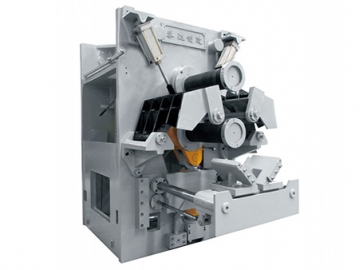

1. The rollers are all forged from high quality structural steel and processed through extensive treatments. The surfaces are all plated in a hard chromium, giving them a high hardness and a long operating life.

2. The power is set to automatically transport the steel sheets with a thickness of 0.5-1.5mm. The machine does not need to be frequently adjusted for clearance between the pressing rolls when pressing the sheets in different thicknesses. This allows the sheets to exit the machine with no scuffing on the coating film. This machine is easy to operate, and guarantees the quality of the finished product.

3. The length of the finished sheet is measured using an electronic measurement instrument or mechanical measurement instrument. The helping hand wheel and the counter are used in the adjustment of the bending of the arch sheet, making operation simple and guaranteeing the quality and dimensional precision.

4. The hoisting tool is light and maneuverable. (A hoisting tool from the United States weighs around 30kg, whereas ours is only 2kg). It is easy to install and remove, and the speed is fast.

Main Technical Specification of CS-914-650 K Q Span Machine

1. Length: Approx. 10.3 m

2. Width: Approx. 2.25 m

3. Height: Approx. 2.30 m

4. Weight: Approx. 13000kg

5. Axle: Three axles, six tires

6. Wheel/tires: Standard

7. Towing: adjustable draw bar height from 80mm-160mm with 80mm round hitch.

8. Lighting System: Easily adaptable lighting

9. Drive System: All hydraulic

10. Fuel tank capacity: 68 liters

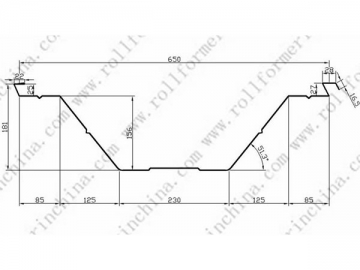

11. Construction: All steel and burnished aluminum construction, precision forming rollers with hard chrome plating.

12. De-coiling Device: 508 mm inside diameter, 5000kg capacity

13. Plant: Premium urethane enamel over epoxy primer (white) with buyers' markings on top and side covers

14. Panel forming speed: Approx. 18 meters/min

15. Curving Speed: Approx. 15 meters/min

16. Seaming Speed: Approx. 6 meters/min

17. Tables:four legs, with rollers, stand separately

18. Minimum Radius: 3.65 meters

19. Steel Coil Capacity: 1.2 mm nominal ASTM 653 Grade 50, 1.5 mm maximum thickness, 0.80 mm minimum thickness

20. Maximum Building Size: 25 meters wide, widths are calculated using liberal code parameters from the International Building Code