Trimming machine

Tube trimming machine, trimmer , tube threading machine

Application of Equipment and Operating Principle

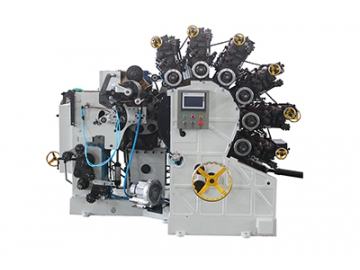

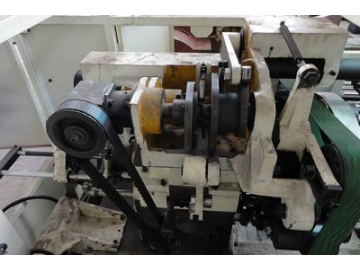

The LWG01 aluminum tube making trimmer is professional equipment of the aluminum tube machine line, which can modify and form the tube. The LWG01 aluminum tube making trimmer is the necessary equipment of the mental tube automatic machine line, and it can be connected with other equipment into the pipeline or be used single. The main process of this machine includes cut the tubes head, press the screw thread of the tube, cut the excess part of the tubes tail and polish the tubes shoulder.

The billet tube is inserted into the central spindle through the charging groove. After the aluminum tube is covered with the expansion central spindle, the expansion arbor begins to expand and the aluminum tube is fixed on the arbor. Then the expansion arbor begins to spin at high speed and drives the aluminum tube to rotate at high speed. The tail of the aluminum tube is cut with a tail cutter during rotation so the length of the tube is reached the requirements. The nozzle is cut by the front cutter to form the neck with the certain height. At the same time, the thread cutter is rolled on the neck of the tube to produce threads of required specifications. Next, the brushing disk is driven by the motor to polish the head and shoulder of the tube to remove burrs. The tail bearing flattens the notch left by the tail cutter to make the tube more straight and easy to take off.

The last station is the unloading station. The stripper plate is controlled by the cam, and the tube blank after processing is pushed down the mandrel, and then enters the charging groove through the guide of the belt. The charging groove can be connected with the conveyor chain of the furnace anneal to enter the next annealing process.

Technical Parameters- Suitable diameter of tube: 16-40mm

- Suitable length of tube: 200mm

- Maximum production rate: 120 tubes/minute

- Total power: 8.35KW

- Dimension: 2800*2500*1900mm

- Weight of the machine: 2800KG

- The specification of extrusion thread: 14mm

- The LWG01 aluminum tube making trimmer uses the fuckson indexer, which is accurate, low noise and wear resistance.

- The LWG01 aluminum tube making trimmer has the function of secondary into the tube and can separate the tail of the tube automatically.

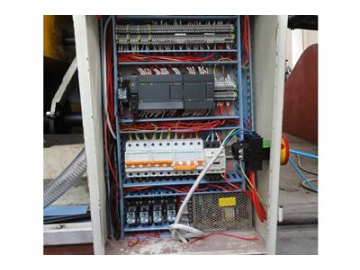

- The LWG01 aluminum tube making trimmer is controlled by Siemens PLC. The text displayer to display real-time production speed and other information at any time.

- The LWG01 aluminum tube making trimmer uses variable-frequency drive to regulate speed, which is convenient and accurate. The central spindle adopts quick change structure and the change of the specification is quick and convenient. The central spindle disk and cam are processed by computer numerical control equipment, which improves the stability during production of the whole machine.

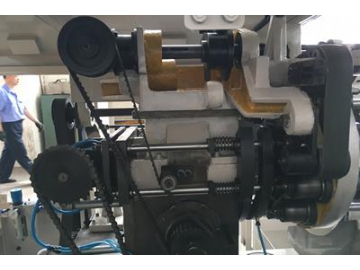

Variable-frequency drive

Variable-frequency drive  Electric machinery

Electric machinery  Electrical box

Electrical box  Indexer

Indexer  Draught fan

Draught fan  Control panel

Control panel  Chain drive

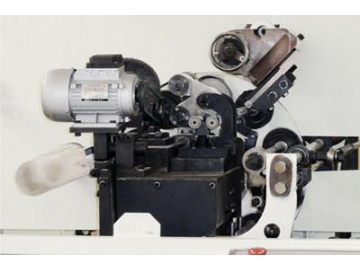

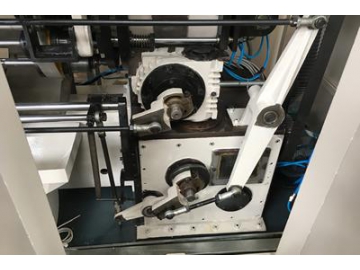

Chain drive  Thread cutter

Thread cutter  Expansion arbor

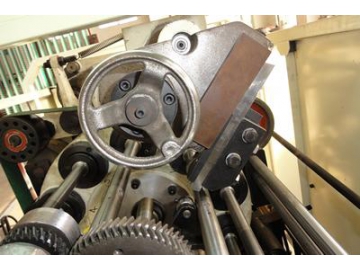

Expansion arbor  Belt transmission

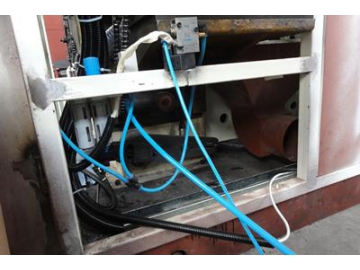

Belt transmission  Gas path

Gas path  Head cutter

Head cutter  Tail cutter

Tail cutter  Transmission chain

Transmission chain  Brush disk

Brush disk  Pushing rod

Pushing rod