Multilayer tube extrusion line

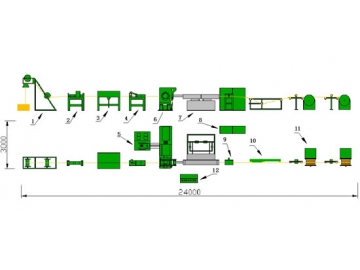

Tube Extrusion Line / Multilayer Tube Co-Extrusion Line/ Precision Tube Extrusion Line

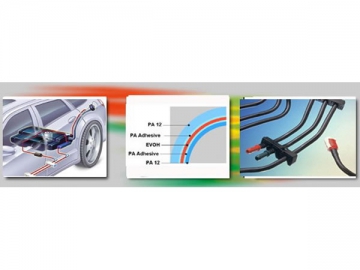

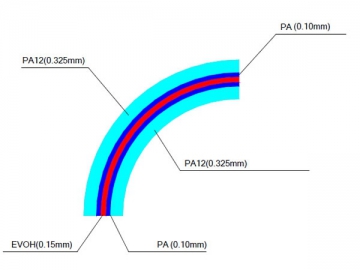

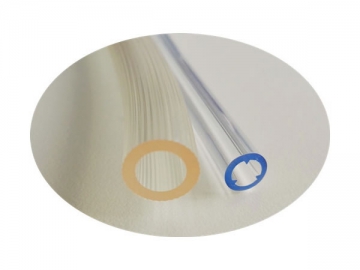

Multi-layer co-extrusion technology development ensures all the tube physical properties and cost control have a great performance, including environmental protection performances in multi-layer automotive tubing, high pressure resistance performances in multi-layer braided tubes, and casing wall lubrication performances. In recent years, the PA multi-layer composite tube for automotive fuel systems has become widely used in car fuel oil systems due to its portable, high performance and environmental protection characteristics.

The multi-layer tube extrusion line has 2, 3, 4 or 5 multi-layer tube types, with an outside diameter of 6, 8, or 10mm for different applications. The PA multi-layer composite pipe can effectively reduce the automobile’s emission pollution and meet higher environmental requirements. As the multi-layer composite pipe features an excellent resistance to penetration, it meets EU-III standards.

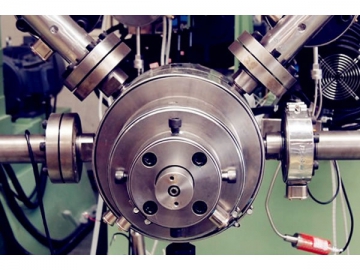

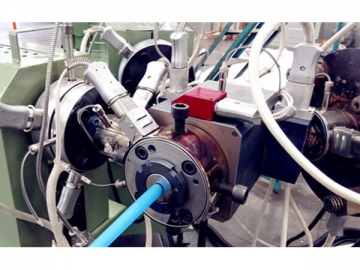

Based on Kingswel Machinery Baochong Extrusion Company’s experience in precision small tube extrusion process technology, and the introduction of German multi-layer co-extrusion die technology, we have developed a stable performance multi-layer tube extrusion line for 3, 4 and 5 layer PA nylon tubes. The production speed of this tube extrusion line reaches anywhere from 10-60m/minute. With a successful partnership with a Japanese terminal user, we have begun promoting the high-end PA pipe extrusion line on domestic auto part markets and other overseas regions.