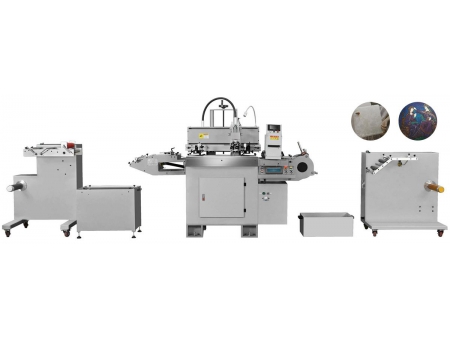

Large Parallel Lift Screen Printing Machine

Features of Screen Printing Machine

1. The parallel lift screen printing machine uses four cylinders for printing, ensuring uniform printing pressure and accurate printing.

2. The printing head is driven by a gear motor, allowing it to lift fast and smoothly.

3. The frame holder is lifted by four columns, which is fast and stable.

4. A high precision guide rail is paired with a Megadyne timing belt; and a dual-frequency system is used to drive printing, allowing the lifting process to be higher and more stable.

5. The oil-water separator and the snap off cylinder form a link, making sure the snap-off is stable and uniform.

6. The large parallel lift screen printing machine uses a microcomputer with fault indicators, making future maintenance quick and easy.

Motor control

Motor control

system

| Model | | | | |

| Max. printing size | 1500×800MM | 1700×900MM | 1800×900MM | 2300×900MM |

| Working table size | 1700×900MM | 1900×1000MM | 2000×1000MM | 2700×1000MM |

| Max. screen frame size | 1800×1000MM | 2000×1100MM | 2200×1200MM | 2600×1000MM |

| Substrate thickness | 0-40MM | 0-40MM | 0-40MM | 0-40MM |

| Instant snap-off height | 0-30MM | 0-30MM | 0-30MM | 0-40MM |

| Max. printing speed | 600T/H | 600T/H | 600T/H | 600T/H |

| Weight | 1200KG | 1500KG | 1650KG | 1800KG |

| Dimensions | 2400×1280×1750MM | 2650×1380×1750MM | 2750×1380×1750MM | 3100×1380×1750MM |