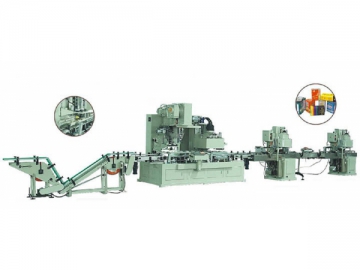

Pail Production Line

Advantages

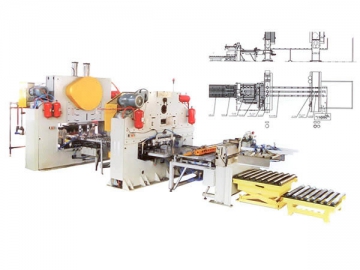

1. Our pail production line makes extensive use of servo motors to do clearance operations. This reduces power consumption and makes the production line more energy-efficient and environmentally friendly.

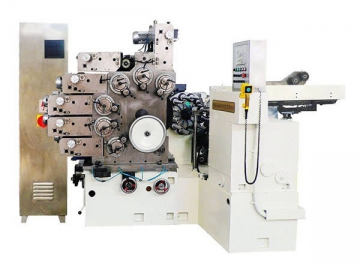

2. This metal container making equipment features a unique nine-wheel seaming technology. This greatly improves the production efficiency and enhances the tightness on can bottoms.

3. The rotary flanging technology is used to achieve multiple functions.

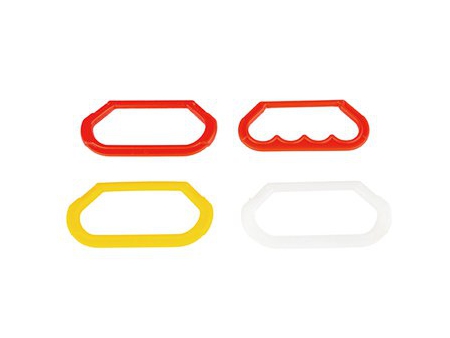

4. Our pail production line can achieve five and seven layer seaming on can bottoms by adjusting the size of flanging and necking. This saves can body materials and improves the tightness of can bottoms.

5. The mechanical cam drive is used to deliver and hold cans.

6. The speed of the barrel making machinery is continuously adjustable.

7. Our pail production line is equipped with a protection device to prevent metal cans from getting stuck, which guarantees a safe and smooth production process.

Technological Process

Vertical delivery of metal can → expanding and pre-coiling → expanding and molding → stamping the wire edge → bulging the rib → U-turn à beading → bottom seaming → finding spot → ear welding

| Dimension (L×W×H) | 14,000×1,750×3,100mm |

| Production Rate | 8-30 cans/minute |

| Voltage | Three-phase four-wire, 380V |

| Air pressure | ≥0.6Mpa |

| Connection Height | 1200±20mm |

| Total Weight | 28T |