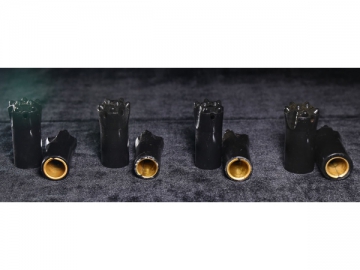

Tapered Button Bits

A tapered button bit is typically installed on an air-powered rock drill and pairs with a tapered hex rod. Applications for tapered button bits abound, including reaming, rock bolting, and tunneling.

At Yanggu, we only source the best steel and cemented carbide from industry-recognized suppliers. Pairing that with our in-house developed processing techniques, we make sure customers receive nothing but the highest quality rock drill bit with maximum wear and delivering fast, accurate drilling operations.

Yanggu tapered button bit is built to outperform those from Atlas Copco and Sandvik, delivering an efficiency 6 to 8 times that of a blade bit. It speeds production, saves hours of tedious work, and reduces labor costs.

Diameter: 32mm-47mm

Button bit insert types: Conical button or parabolic or ballistic buttons

Connections: 4°, 6°, 7°, 11°, 12°taper

Number of buttons: 3,4,5,6,7,8,9, etc.

We do all the forging, machining, heat treating, stamping and shrink-fitting in-house, with the aid of our tools and dies, inspection equipment, tooling equipment, metal materials, and of course, our professional production workers and design engineers. Tools and dies are engineered using 3D computer-aided design software. That is why we can deliver your order fast. We can customize a taper drill bit as well based on client-supplied technical drawings, samples and products.

Good to Know

Shrink fitting is used to press fit button-bit-inserts into pre-drilled holes in the button bit. It uses heat to expand the hole, then fits the insert into the hole, and cools it so that the hole shrinks back to hold the inserts. Button bit inserts are often available into two types: conical inserts and chisel inserts.