Spherical Roller Bearings

Spherical roller bearings are designed with two row rollers running between an inner ring of two raceways and an outer ring with a spherical raceway. This allows these bearings to support both an axial and radial load, and the high radial load capacity ensures the spherical roller bearings are ideal for heavy load or impact load conditions.

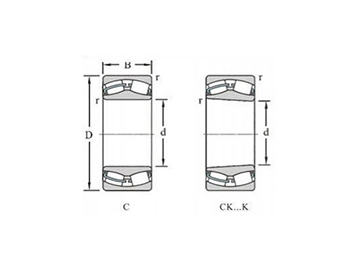

Shown in the figures, types C, CK…K, CA and CA…K, which are designed for high load capacity, are available. Types C and CK…K have pressed steel cages, and Types CA and CA…K has machined brass cages.”

An oil groove and holes are provided in the outer ring to supply lubricant and the bearing numbers are suffixed with E4.

To use bearings with oil grooves and holes, it is recommended to provide an oil groove in the housing bore, since the depth of the groove in the bearing is limited.

When bearings with a hole for a locking pin to prevent outer ring rotation are required, please inform GXB.

Permissible MisalignmentThe permissible misalignment of spherical roller bearings varies depending on the size and load, but it is approximately 0.018 to 0.045 radian (1°to 2.5°) with normal loads.

Limiting SpeedsThe limiting speeds listed in the bearing tables should be adjusted depending on the bearing load conditions. Also, higher speeds are attainable by making changes in the lubrication method, cage design, etc.

Main applicationSpherical roller bearings feature a wide array of applications, including paper machinery, speed reducers, printing machinery, woodworking machinery, crushers and more. We offer two bearing types, comprised of cylindrical and tapered holes. Among which, users can not only install the tapered hole bearings directly, also can mount it on the cylindrical axis using an adapter sleeve and a bushing. We offer customized spherical roller bearing size.

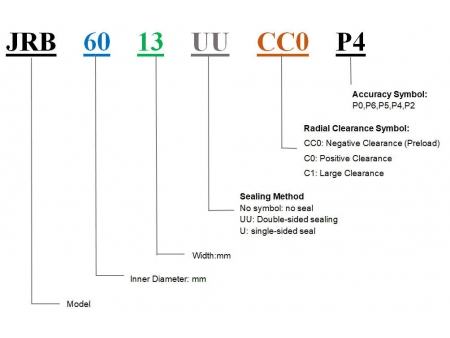

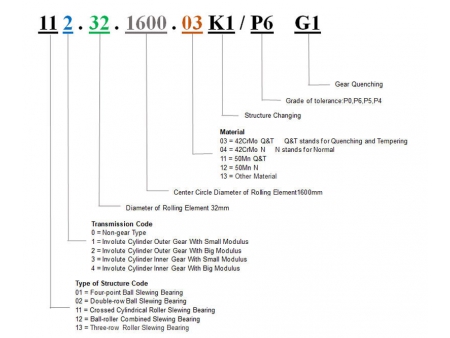

Parameter