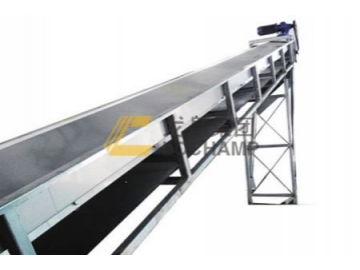

Long-distance Curved Belt Conveyor

Overland conveyor is a horizontally curved conveying system that provides the most effective method for transporting bulk materials across long distances and rough terrains. Zoomry overland conveyor system can be flexibly installed to adapt to very undulating terrain, and bypass mountains, obstacles or existing buildings via horizontal curves.

Zoomry has the ability to design and manufacture the overland belt conveyors that are tailored to meet customer's specific needs of the material type and handling capacity, and work out long-distance bulk material handling solutions that are oriented to accommodate the existing topography and climatic conditions at target areas.

- Belt width 500mm-2600mm

- Length Up to 20km

- Capacity 0-15000m3/h

- Lump size ≤300mm

- Belt speed 1.0~6.5m/s

- Turning radius 100m~3000m

- Turning angle 0-90°

Long-distance transportation of materials under complex terrain conditions generally requires a large amount of earth works, more transfer stations, higher labor intensity and energy use. We have been designing long-distance overland conveyors across various applications for over 20 years, this means we have the knowledge and design expertise to help customers reduce site preparation works, extend system maintenance cycles and lower energy consumption.

Zoomry overland belt conveyors can be built with length of more than 15km for long-distance material transporting, and horizontal curves allowing the conveyor to run through hilly terrain and existing buildings.

- 01. Eco-friendly The unique design of noise and dust control secures your materials and protects the environment against noise and dust pollution during the long-distance conveying process.

- 02. Energy efficient The energy efficiency of the belt conveyor is significantly improved by using clean electricity energy, resulting in cleaner production without air pollution and exhaust gas.

- 03. Safe Since there are no traffic resources that are occupied, the overland conveyors can efficiently avoid potential safety hazards that may occur in automobile transportation.

- 04. Flexible Curved transport route can better accommodate the local geographic and topographic conditions, safely negotiating varied terrains, buildings and roads.

Long-distance curved belt overland conveyor is extensively used in bulk material handling applications in mines, ports, cement plants, aggregates plants, loading points, and other a variety of raw material plants. It is an ideal alternative to conventional long-distance conveying methods using haul trucks or multiple belts.

- Comprehensive analysis of site environmental conditions

- Custom-designed conveyor system

- Wide options of conveyor belt length and width

Apart from designing and building of complete overland conveyor system, Zoomry also offers conveyor components which are all manufactured in-house to ensure the high reliability of our conveyor systems.

Idler/Roller

Idler/Roller Conveyor Pulleys

Conveyor Pulleys Belt Cleaners

Belt Cleaners Conveyor Covers

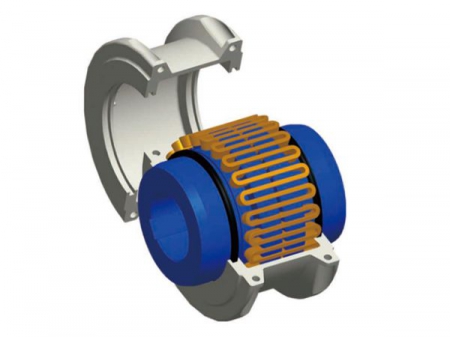

Conveyor Covers Spring Couplings

Spring Couplings Impact Beds

Impact Beds

Inner Mongolia Mengxi Cement Group

Project time: 2013

Material: limestone

Handling capacity: 1200t/h

Belt width: 1200mm

Conveyor length: 4650m

Solution: long-distance curved belt overland conveyor, 6 horizontal curves with radius ranging between 1000m and 1500m

Our company's business integrates consulting design, manufacturing, installation, after-sales, and operation services. There are professional teams and perfect processes in each stage of project execution. In terms of design, we have our own on-site construction supervision team to feedback the actual operation data and equipment life, which helps to grasp the most accurate usage data for verifying and improving our overall design. In addition, the core components of the telescopic stacker are all produced by our company. The structure and process improvements accumulated over the years ensure the stable and reliable quality of our equipment.