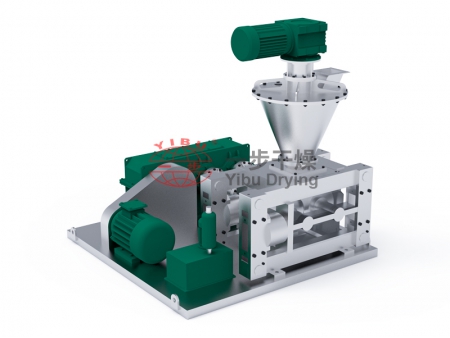

Roller Compactor Granulator

The roller compactor granulator uses dry pressing technology to compress material with moisture content lower than 10% into sheets and it is then broken into granules for treating and further screening processes.

The material is pressed by extreme force when it passes through the gap between the two rollers, which are rotating in opposite directions. The material is pressed into sheets with a density 1.5-3 times that of the loose raw product.

Petro-chemical, fine chemical, pharmaceutical, foodstuff, metal powder, bio-engineering, pesticide, fertilizer, mining and coal.

| Items Parameters Models | |||

| Diameter of roll(mm) | Φ240 | Φ360 | Φ450 |

| Width of roll(mm) | 80-160 | 180-500 | 220-1000 |

| Revolution of roll(rpm) | 15,20,26,32 | 14,18,24,30 | 10-25 |

| Max. Pressure of roll(mpa) | 120 | 160 | 210 |

| Max. Thickness of pill(mm) | 4 | 8 | 8 |

| Capacity of pill(kg/h) | 200-500 | 500-3000 | 800-5000 |

| Diameter of finished pill(mm) | 0.5-6 | 0.5-8 | 0.5-6 |

| Capacity of finished product(kg) | 160-400 | 400-2400 | 680-4000 |

| Power of main machine(kw) | 7.5 | 22-37 | 45 |

| Total power(kw) | 20 | 50 | 80 |

| Overall dimension(L*W*H)(mm) | 1500x1300x5000 | 2000x2000x9000 | 2500x2500x10000 |

| Weight(t) | 6 | 10 | 13 |

The material enters into the hopper lifting machine through a spiral conveyor from the feeding port, and then it is delivered to the vibration material silo. A metered feeder will feed the material into an inverter controlled spiral feeder, and the material is then pre-pressed. The pre-pressed material enters into the gap between the two rollers that are rotating in opposite directions, and it is firmly pressed. The firmly pressed material sheet falls into the breaking machine automatically, and is then smashed into granules of different sizes. The trimmed granules are squeezed out into the sieve through a mesh board. The final product enters into hopper lifting machine, and then it is conveyed to the finished product silo. The material sieved out should be fed back to the material silo by spiral conveyor, so to perform the next circulation.

- Hopper Lifting Machine

- Fine Power Recycle

- Particle of Product

- Grinding and Granulation Device

- The material is pressed by the rolling machine, without any additional ingredients to ensure purity.

- The dry material is made into granules directly, no need for any further drying processes.

- Compressing the material helps prevent wasted powder and decrease packaging fee with the higher density product.

- The material feeding utilizes a non-step inverter control for a high level of automation.

- The roller compactor granulator is produced from high quality alloys, stainless steel, Ti, Cr and other materials because of their wear resistance, corrosive resistance, heat resistance and pressure resistance.

Need help finding the right product? Please fill the form and we will be in touch with you as soon as possible.