Food Process Extruder with Single Screw

Introduction

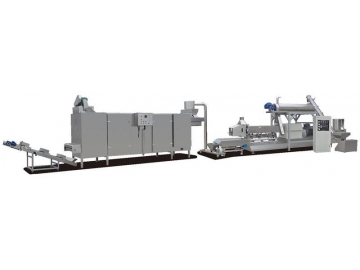

1. The food process extruder with single screw consists of a feeding system, extrusion system, rotary-cut system, heating system, drive system, cooling system and control system. It is used in fried food processing operations.

2. Frequency control offers strong power and delivers stable operation. It is used in the machine’s feeding system, driving system and rotary-cut system.

3. To balance the temperature of materials during extrusion, the extruder screw, cylinder and mold are designed with a circulating cooling system.

4. The screw has undergone a nitriding treatment process. This delivers wear-resistance and antifatigue properties to maximize durability.

Technical parameters| Model | Installed Power | Actual Consumption | Main motor consumption | Throughput | Dimensions | Products | |

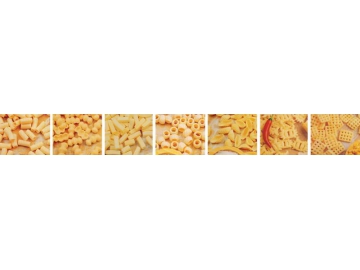

| SX2000-100 | 45KW | 28KW | 30KW | 80-100Kg/h | 3.5x1.05x1.96m | Second puffed foods | |

| SX3000-100 | 45KW | 30KW | 30KW | 80-100kg/h | 3.2x1.05x1.96m | Second puffed foods |

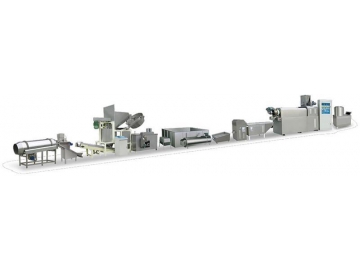

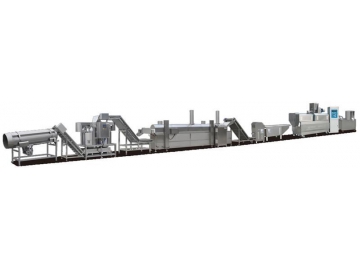

The food process extruder with single screw can be connected to other equipment to form a food production line

1. Mixer → Food process extruder with single screw → Post-extrusion cutter → Cooling bed → Automatic frying machine → Automatic seasoning equipment is used in

2. Mixer →Food process extruder with single screw → Transport cutter → Cooling bed → Hot air drier→ Automatic frying machine → Automatic seasoning equipment is used in

3. Mixer → Feeding machine → Food process extruder with single screw → Blower→ Spreader → Conveyor → Fryer → Seasoning equipment is used in

Index

food equipment, snack machine, biscuit manufacturing machine, fried food processing