HYF4.5-HYF40 Nonwoven Geotextile

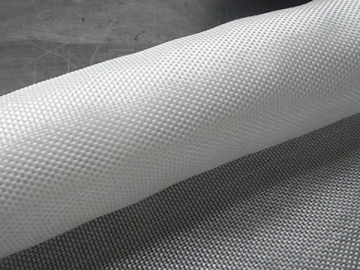

HAOYANG HYF series nonwoven geotextile fabric is a continuous filament spunbond nonwoven needle punchedpolyester geotextile, made of 100% virgin polyester resin, this geotextile is used in protection, separation, filtration andreinforcement applications. Haoyang's production line adopts the international advanced technology industries and thefirst time in the application of advanced twin-screw extrusion technology,dual-array wire system, pipe flow distractiontechnique, plate wire systems and high-speed needle placed into the fabric production process, 18 international anddomestic patents, the product has high strength,anti-aging, acid, abrasion resistance, good flexibility, easy construction.

Product Specifications| Tested Property | Unit | Test Method | HYF4.5 | HYF7.5 | HYF10 | HYF15 | HYF20 | HYF25 | HYF30 | HYF40 |

| Tensile Strength ≥ | kN/m | ASTM D 4595 | 4.5 | 7.5 | 10 | 15 | 20 | 25 | 30 | 40 |

| Tensile Elongation | % | ASTM D 4595 | 40~80 | |||||||

| Trapezoidal Tear ≥ | kN | ASTM D4533 | 0.14 | 0.21 | 0.28 | 0.42 | 0.56 | 0.7 | 0.82 | 1.1 |

| CBR Burst Strength ≥ | kN | ASTM D 6241 | 0.8 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 |

| Permeability | cm/s | ASTM D 4491 | 0.1-0.8 | |||||||

| Apparent Opening Size O | mm | ASTM D 4751 | 0.05~0.20 | |||||||

| Thickness ≥ | mm | ASTM D 5199 | 0.8 | 1.2 | 1.6 | 2.2 | 2.8 | 3.4 | 4.2 | 5.5 |

| Mass Per Unit Area | g/m2 | ASTM D5261 | 110 | 150 | 200 | 300 | 400 | 500 | 600 | 800 |

| Mass Variation | % | -5 | ||||||||

| Width Variation | % | -0.5 | ||||||||

| Typical Roll Width(40'HC) | m | 5.92 | 5.92 | 5.92 | 5.92 | 5.92 | 5.92 | 5.92 | 5.92 | |

Material: PET

Specification: 100g-800g/m2

Width of non-woven fabric: 1m-6.4m

Length of non-woven fabric: 50m-150m or as required by customers

Color: white, black, green, grey, or as required by customers.

Package: roll, outer PE membrane, or woven fabric, or as required by customers.

Production ability: 10000m2/day.

This HYF4.5—HYF40 nonwoven geotextile is mainly utilized in the construction of highways, railways, dams, coastal installations, waste management centers, etc. for reinforcement, filtration, separation, and drainage.

1. Filtration

These PET geotextiles are used as a filtration layer for dykes, canals, concrete retaining walls, and other water filtration applications. The fabric allows water to pass through while preventing soil and other large particles from doing the same.

2. Isolation

The fabric is also used as an isolating layer between the subgrade and ballast of railways, as well as between pavement and foundation soil for a number of construction projects. It can also be used to differentiate between damn layers, isolate sand and other sedimentary materials.

3. Reinforcement

The high strength geotextile fabric is often found in the construction of roads, railways, earth-rock dams, breakwaters, airports, and retaining walls. The fabric absorbs stress in order to prevent lateral soil movement and maximize the stability of the construction project.

4. Protection

In order to prevent soil erosion caused by wind, water, rain and other elements, the fabric can be used to cover the area.

3 typical joint connections for needle-punched non-woven geotextile: lap joint, welding and suturing.

PET FilamentSpunbond Nonwoven Geotextile

This nonwoven geotextile fabric is a spunbond polyester continuous filament needle punched material made from 100% virgin polyester resin. Haoyang's production line uses internationally advanced, twin-screw extrusion and dual-array wire system technology with pipe flow distraction, plate wire systems, and high speed needle punching in order to produce fabric that is extremely strong, resistant to aging, acid/abrasion, and flexible. This particular geotextile and its related production processes has earned 18 international and domestic patents.

The fabric can be manufactured with a surface treatment through hot rolling and flame singeing on one or both sides.

Strong physical durability

High density

Flexible structure

Corrosion resistant

Anti-aging

Acid-and-alkali-resistant

Good water absorption and permeability

Excellent filtering and isolation performance

Haoyang is a leading environmental protection service provider, a manucturer, marketer and installer of geosynthtic products and service. We deliver consistancy of products and service to our customers through our expertise and professional team with the determination to serve our customers and protect our enviroment.

Our national approved R&D Center focuses on new material, product and project innovation; our team of expertise focuses on quality and customized products, giving us the strength to handle challenging projects to guarantee our clients' success.

This geotextile fabric is a polyester continuous filament needle punched nonwoven geotextile, It has been widely used in Asia, Africa and australia.

According to the weaving process, the product can also be called simply: nonwoven geotextile; pet nonwoven geotextile;pet needle punched geotextile; needle punched non woven geotextile; needle punched geotextile;pet needle punched nonwoven geotextile; filament spunbond geotextile;long fiber non woven geotextile; filament geotextile;continuous filament geotextile; filament nonwoven geotextile.

We can also provide the geotextile postprocessing, so called: singeing geotextile;hot rolled geotextile; hot ironing geotextile; heat setting geotextile.

According to the application, they can also be referred to as filter geotextile, protective geotextile, reinforced geotextile, and insulating geotextile.

Many European and American customers request the filament needle punched non-woven fabric is polypropylene filament material, we can also provide, please check our products series .